Once the surface to be painted is completely clean, it should first be

painted using anticorrosive paint, preferably a "zincromat"-type base

coat, applied both inside and outside the spiral and suction tube. After

the base coat has been applied, putty should be used to cover any parts

requiring this in order to obtain an improved finish. Once the putty has

dried it should be sanded down first with a course-grain abrasive

followed by a fine grain and lastly a water abrasive. Before the finishing

paintwork is applied, which could be with vinyl paint or any other type of

paint for metal, the structure should again be cleaned with rags and

thinner in order to remove any dirt and possible grease which may have

built up during handling. Finally, the finishing paintwork is applied with

the required uniformity. A spray gun should ideally be used, in which

case this should first be inspected to ensure the nozzle is completely

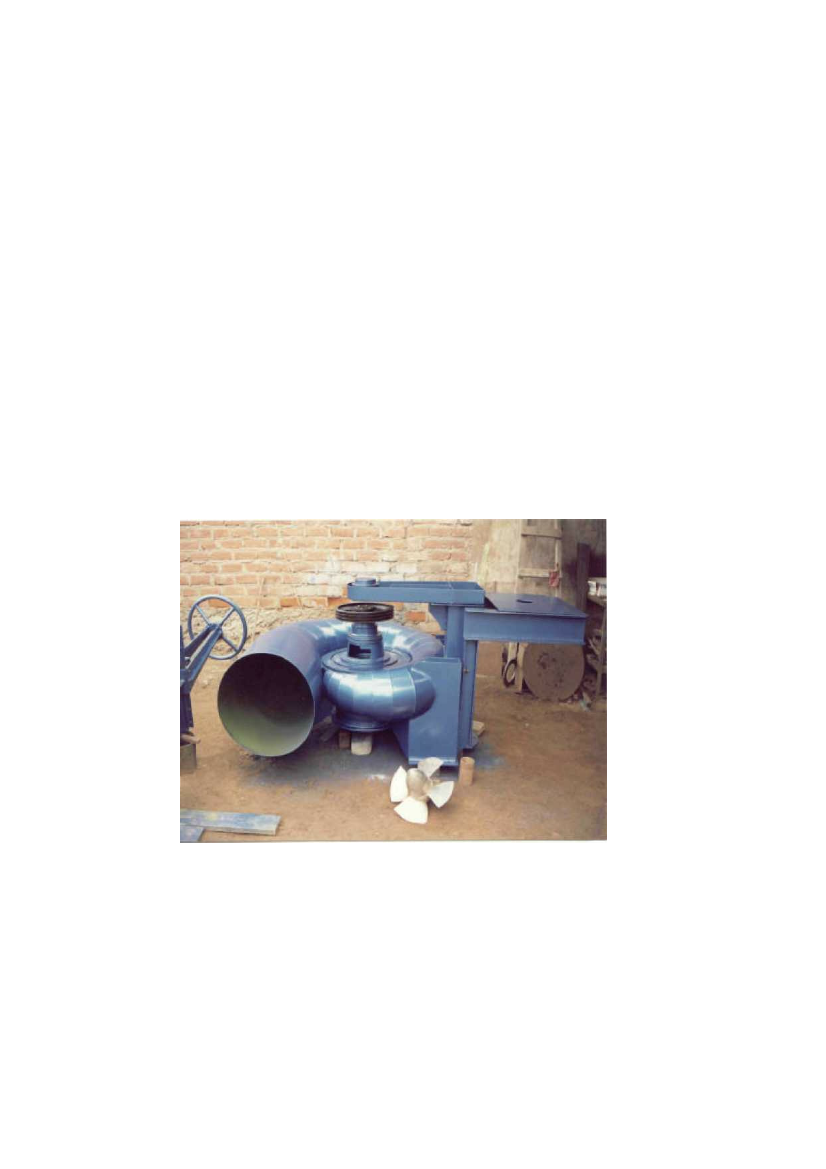

free of obstructions and paint residue. (Fig. 14)

Figure 14: Finished axial turbine

2.2 Manufacture of the suction tube

The suction tube is manufactured using the same materials as the spiral,

and also the same equipment and tools.